In the military and aerospace industries, vertical integration has become the moat that separates leaders from competitors. Defense programs demand more than performance—they require supply chain security, predictable cost, and rapid innovation across the product life cycle. Companies that depend on fragmented subcontractors cannot keep pace and are a thing of the past. Funding or investing in capital for full vertical integration provides the sustainable competitive advantage that ensures capabilities are delivered at speed and scale.

Clear Align is built on this model. As a vertically integrated platform, the company manages every stage of optical fabrication and advanced manufacturing. From boule cutting and CNC machining to MRF polishing, thin-film coatings, and final sensor integration, Clear Align controls production. This approach secures the supply chain, lowers risk, and enables defense primes to access systems that are both reliable and rapidly deployable.

Scale & Vertical Integration Enables Scale and Future Growth

Vertical integration for national defense is more than reducing the business expense of new technology. It is a long-term strategy that ensures stability, protects intellectual property, and enables companies to develop new capabilities quickly and outpace competition. By vertically integrating, defense firms reduce dependence on outside suppliers, improve efficiency in manufacturing, and protect their company market position.

Leaders such as Lockheed Martin and Raytheon have proven the value of this approach. They integrate raw materials, advanced manufacturing, and system development under one company, which allows them to iterate quickly and deliver new products in response to demand. Clear Align applies the same principle to optics and C5ISR systems, making the company a trusted partner to primes and government agencies that require both specialized components and complete solutions.

Vertical integration also strengthens relationships with the customer base as you invest to create novel approaches to new threats. For defense primes balancing risk, cost, and speed, a vertically integrated partner provides confidence that programs of record will not be delayed or disrupted by third-party bottlenecks. This assurance is increasingly valuable as the industry navigates persistent challenges in supply chain security and defense industry mergers that reduce competition.

Leading Industry Trends and Challenges for Systems Integration

The defense industry is experiencing a new wave of mergers and acquisitions, with firms consolidating to secure manufacturing capacity and expand their customer base. While these moves increase scale, they also reduce competition. The Pentagon has voiced concern that fewer new entrants and more consolidation could harm innovation.

At the same time, global supply chain challenges and rising costs threaten production. Rare-earth materials, semiconductors, and optics are critical, and disruptions have raised risk across the industry. In recent years, these pressures have highlighted the need for vertically integrating key processes to control production, manage cost, and ensure access to essential key materials.

Foundation Models for a Demanding Market

A foundation model is a large-scale artificial intelligence (AI) model, typically a neural network, trained on vast amounts of diverse, often unlabeled, data using unsupervised learning. These models are designed to be adaptable and can be fine-tuned for a wide range of downstream tasks, such as language understanding, image generation, and coding, rather than being built for a single, specific purpose.

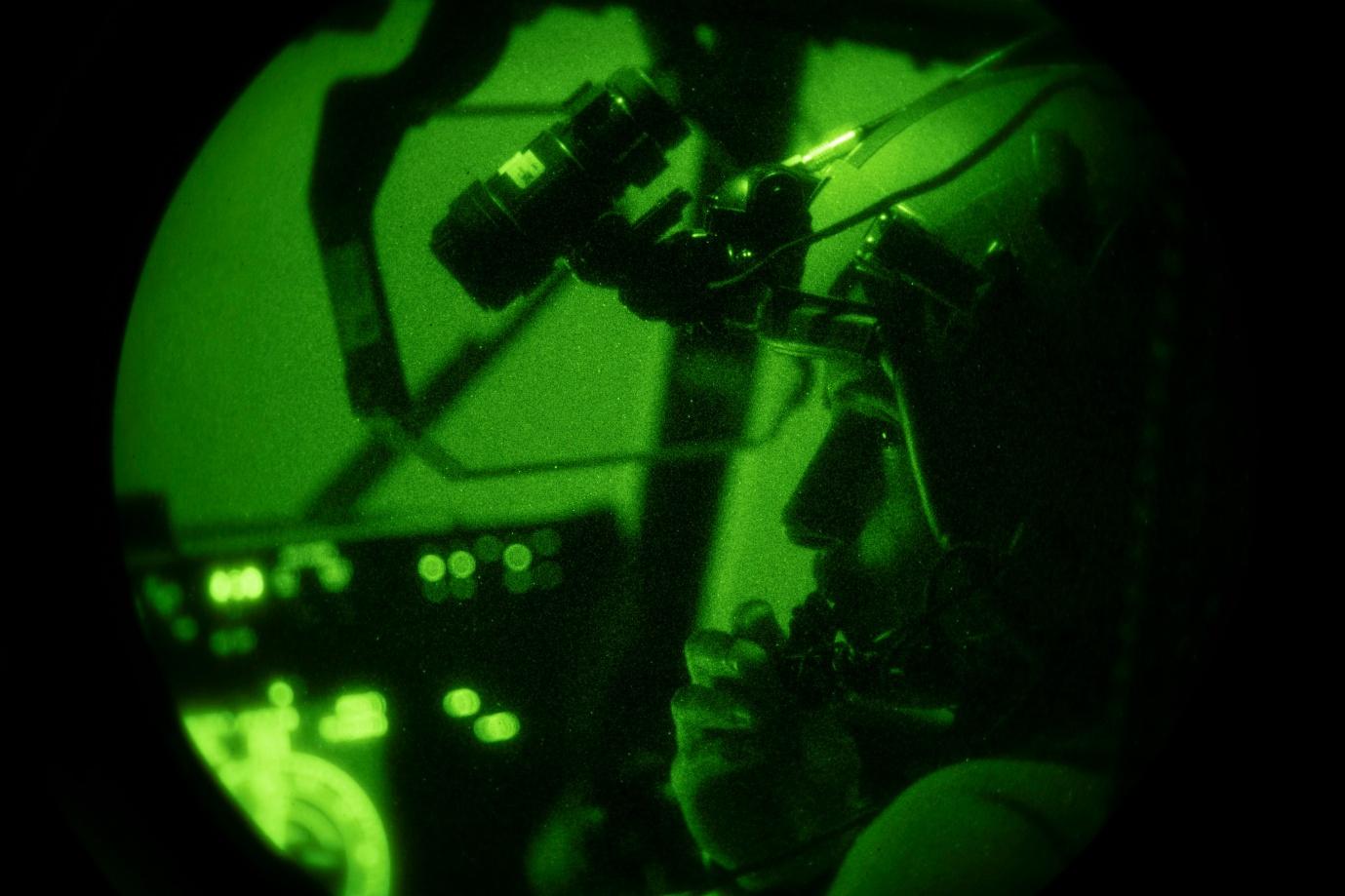

Clear Align solves the issue of labor for video evaluation and invests in AI and ML (machine learning) to scale our clients operations. For example our remote Mamba product can be hand carried to locations and monitor areas for people, aircraft or vehicles autonomously addressing many of the challenges today’s proliferation of cameras can create.

Clear Align’s Technology Solves Many Manufacturing Hurdles

Clear Align has invested heavily in U.S.-based advanced capital intensive manufacturing facilities as well as AI and ML for the ability to innovate at a material level with funding from major prime contractors. Its vertically integrated operations eliminate customers concerned foreign supply chain dependencies and create a secure network for critical defense programs. By consolidating optical fabrication and integration, the company provides predictable cost models and lifecycle sustainment that primes can count on for long-term contracts.

Optical fabrication remains at the heart of this strategy. Germanium, silicon, and specialty raw materials are processed from raw form to finished optics entirely within Clear Align’s facilities. That capability ensures consistent quality and cost control. But the company extends beyond optics: it integrates payloads, electronics, and command-and-control into full C5ISR systems. This dual capability distinguishes the company in a defense market where many firms specialize narrowly.

Benefits of Vertical Integration

The benefits of vertical integration in defense manufacturing extend across performance, cost, and innovation.

- Supply chain control: Reduced reliance on third parties and protection from external risk.

- Cost efficiency: Streamlined manufacturing lowers cost while providing predictable contract models.

- Rapid innovation: Vertically integrating production enables companies to iterate quickly and deploy new capabilities at high speed.

- Lifecycle technology sustainment: Consistent processes ensure system reliability across decades of service.

- Competitive advantage: Owning the process strengthens long-term market position and secures revenue persistence.

These advantages are not abstract. Clear Align delivers them daily, providing primes with the systems and solutions they need to meet Air Force, Army, and Navy program requirements.

Serving the Primes

For defense primes, the difference between a brokered supplier and a vertically integrated partner is decisive. Clear Align’s model delivers contract stability, faster development, and secure U.S.-based production. By vertically integratingoptical fabrication with C5ISR system integration, Clear Align provides both the critical component and the finished system—eliminating inefficiencies in the existing system of fragmented subcontracting.

This capability also attracts new entrants into the defense industry. By offering manufacturing-as-a-service, Clear Align lowers barriers for innovators to develop new products, strengthening the overall market and encouraging competition.

The Strategic Imperative

The fragility of the global supply chain has made vertical integration a national security requirement. Recent years have exposed risks across defense manufacturing, from semiconductor shortages to rare-earth dependencies. Consolidation has added further pressure, reducing competition and increasing concern about the resilience of the defense industrial base.

Clear Align anticipated this shift. Its investments in advanced manufacturing, system integration, and data-driven process control position it as both a manufacturing provider and a systems innovator. The company delivers today’s capabilities—while building the platform for future requirements such as hyperspectral imaging, AI-enabled targeting, and next-generation electro-optical systems.

Looking Ahead

The defense industry is entering a new paradigm. Unmanned aircraft systems, AI-enabled decision support, and advanced EO/IR sensors are reshaping operational requirements. But no matter how advanced the technology, it will fail without a secure supply chain and reliable production. Vertical integration provides that anchor.

Clear Align sits at this intersection. By combining vertically integrated optical fabrication with C5ISR system development, it delivers the resilience, cost control, and innovation that primes require. For the defense industry, vertical integration is not just a business strategy—it is the foundation for future innovation. For Clear Align, it has been the guiding strategy all along.