Propane safety and performance depend on the design, testing, and structure of the tanks used every day. Customers often encounter DOT, TC, and ASME certifications early in their research.

These markings may appear simple at first glance, but they define how a tank behaves during travel, outdoor cooking, RV use, or stationary installations. Understanding these standards helps users choose equipment suited to their lifestyle while promoting safer handling in daily situations.

Why Standards Matter for Propane Users

Standards establish expectations for construction strength, testing schedules, and long-term performance. Propane operates in homes, campsites, workshops, and commercial spaces, each exposing a tank to different stresses.

Agencies created structured certification systems to define how a tank must be built and inspected. Cylinders designed for transport follow one set of rules, while stationary tanks follow another. The result is a system that aligns engineering standards with real-world use.

What DOT Certification Covers

A DOT propane tank follows rules set by the United States Department of Transportation. This certification focuses heavily on mobility because these cylinders travel in cars, trailer hitches, RV compartments, and delivery trucks.

Tanks carrying this label are frequently transported, so testing emphasizes pressure performance, wall thickness, and safe venting during travel. DOT cylinders undergo stress tests that mimic rough handling, road vibrations, and temperature changes. These tanks are common in grilling setups, camp kitchens, tailgate events, and small heaters, offering convenient fuel swaps.

Routine inspections are essential, and DOT-labeled cylinders must be requalified after a set number of years to confirm that their structure continues to meet agency standards. This schedule keeps older or compromised tanks out of circulation and maintains safer use.

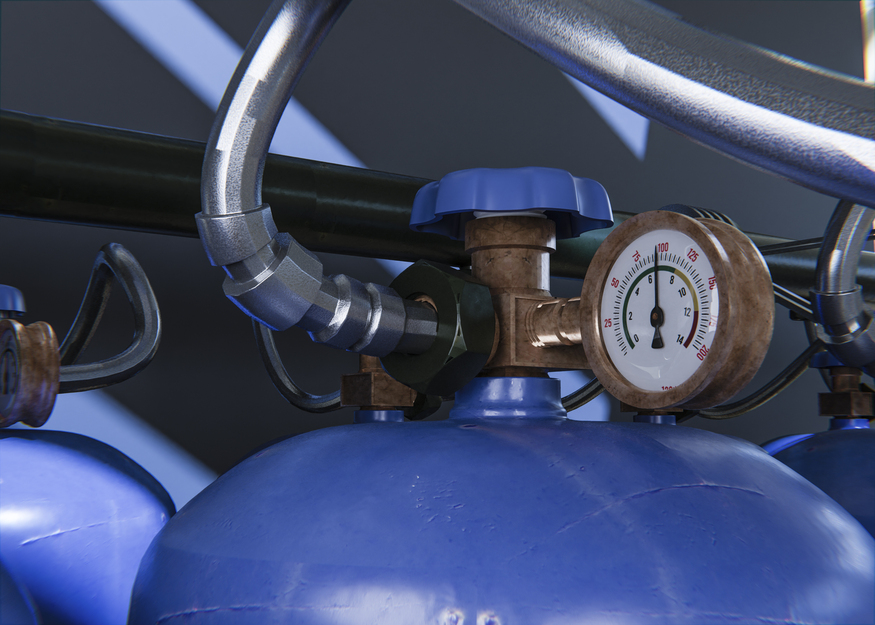

Accessories matter in this category as well. Many users pair DOT tanks with gauges, extension hoses, or quick-connect fittings. These propane accessories help create stable performance because they match the size and threading of portable cylinders.

What TC Certification Means in Canada

Transport Canada (TC) sets rules for cylinders used in outdoor cooking, camping, heating, and job-site tools. TC standards mirror many DOT requirements, including impact tests, burst pressure tests, and valve performance checks. These measures protect users traveling in climates with large temperature swings.

Some manufacturers produce cylinders that meet both DOT and TC certifications, simplifying use for travelers crossing the U.S.-Canada border. These dual-certified tanks reduce the need for replacement purchases and simplify refilling stops. This makes DOT, TC, and ASME certifications essential for those who navigate multiple regions.

What Sets ASME Apart

An ASME propane tank is built according to standards set by the American Society of Mechanical Engineers, with a focus on stationary or semi-permanent use. These tanks are commonly found on RV frames, outdoor kitchens, food trucks, residential heating systems, and larger commercial installations.

Designed to remain in place for extended periods, ASME tanks follow heavier construction standards to withstand long-term exposure to weather, vibration, and repeated heating cycles. They differ from portable cylinders in several ways, holding more fuel and featuring permanent labels instead of temporary inspection stickers.

Periodic recertification is not required, as their design and testing already account for long-term stability. Thicker walls, welded seams, and rigorous standards guarantee reliable performance under continuous use for many years.

RV drivers depend on ASME tanks for a consistent fuel supply during long trips, with the tank securely mounted to the vehicle to maintain stability over thousands of miles. Outdoor kitchens also benefit from the reliability of ASME units, powering grills, side burners, space heaters, and smokers without frequent swaps or refills.

How These Certifications Affect Daily Use

Propane users feel the influence of certification rules each time they cook, heat, or travel. A backyard cook using portable cylinders interacts with DOT standards whenever tanks are swapped at a refill station.

Campers crossing the U.S.-Canada border notice how DOT and TC requirements affect cylinder availability. Full-time RVers rely on ASME construction for consistent performance during long journeys through national parks or desert highways.

Selecting the right certification depends on lifestyle. A homeowner who grills once a week may only need a standard portable cylinder meeting DOT testing. Travelers camping in varied climates often prefer a tank with both DOT and TC markings. Those seeking a stable fuel source for a permanent outdoor kitchen may choose the durability of an ASME tank.

Construction Differences You Should Know

DOT and TC cylinders use lighter steel to support easy movement. The wall thickness supports safe transport while remaining light enough to lift. ASME tanks use much heavier steel that stands up to constant pressure cycles and outdoor exposure.

Stationary tanks often include protective housings, welded brackets, and reinforced mounting points. Valve designs also differ: portable cylinders feature valves suited for frequent connection and disconnection, while stationary tanks rely on fittings designed to remain in place.

Accessories should match the certification type, as thread patterns, regulator sizes, and hose lengths vary. Using compatible components prevents flame drops or pressure loss during cooking or heating.

Inspection and Lifespan Differences

DOT and TC tanks follow scheduled requalification because travel, bumps, and handling stress the structure over time. The inspection process verifies that the cylinder still meets performance standards.

ASME tanks avoid these periodic checks because their construction already covers long-term structural strength. Their fittings still require routine attention from the user. A quick inspection of hoses, regulators, and connectors helps maintain consistent pressure during daily use.

Longevity differs by environment. A backyard cylinder exposed to salty air may require replacement sooner than one stored in a dry garage. An ASME unit mounted under an RV may face road debris, moisture, and heat. Simple care habits add years to the lifespan of both portable and stationary equipment.

Making Standards Work for You

Recognizing these certifications helps users make the appropriate decisions. A tank built for the right purpose produces steadier flames, smoother heating cycles, and fewer interruptions during travel or cooking.

Matching the certification to the activity reduces frustration during refills or swaps. It also supports a safer setup in homes, campsites, or RV parks.

A little research before buying a tank goes a long way. Shoppers who pay attention to certification markings, construction quality, and accessory compatibility build outdoor setups that last longer and perform more reliably.

Knowledge of propane tanks, fittings, and testing cycles helps every user feel more confident as they cook, travel, or relax outdoors.