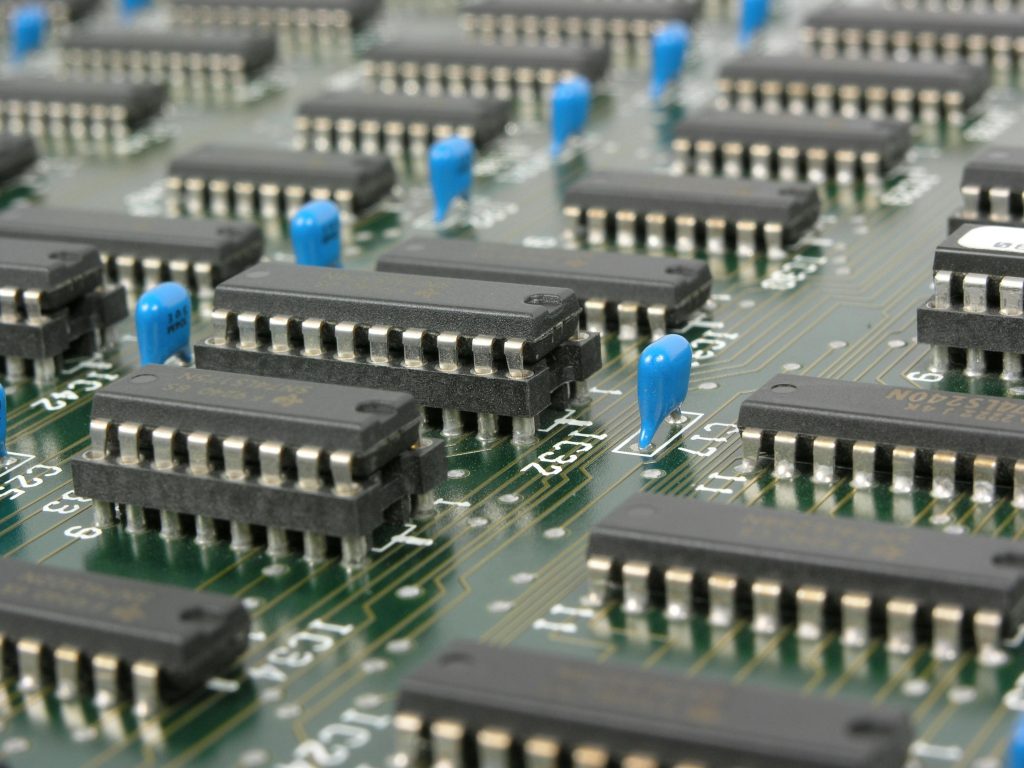

Among the abundance of components making up electronic circuits, very few are as important as capacitors. These components, taking the form of conductive plates separated by an insulating material known as a dielectric, store energy in an electric field and release it when the given application requires.

But when you are looking to design circuits that may depend on the use of capacitors in both parallel and series configurations, what will be the broad steps involved in this?

Below, we have sought to answer this question with an in-depth tutorial.

Step 1: Define Your Circuit Goals

Are you, for instance, looking to build a low-pass filter for audio? Does your project require you to smooth out the voltage in a power supply? Is your target capacitance available as a single component, or will you need to utilise multiple capacitors in an optimal configuration?

When designing a circuit with series and parallel capacitors, your circuit goals should be defined by the electrical properties you are looking to achieve.

Given that series and parallel arrangements impact on total capacitance, voltage handling, and current distribution in opposite ways, your objective will dictate the appropriate configuration.

Step 2: Choose The Configuration Based on Your Needs

Your decision on whether to go with a parallel or series capacitor arrangement, will depend on how you want to affect the total capacitance, voltage, and reliability of your circuit.

In summary, you should opt for a parallel configuration if you wish to increase total capacitance. Alternatively, you might want your circuit to be able to handle higher voltages – in which case, a series arrangement is typically the one to select.

Remember: a parallel arrangement involves capacitors being connected side by side, with their terminals linked to the same two nodes in the circuit. When capacitors are in series, meanwhile, this means they are connected end-to-end, forming a single path for charge to flow.

Step 3: Calculate Total Capacitance

There are two obvious ways to figure out the total capacitance (Ctotal) of a circuit where capacitors are laid out in series or parallel configurations: by undertaking manual calculations, or turning to a dedicated parallel and series capacitor tool to do the workings-out for you.

You can find such calculators in various places – for example, embedded in circuit design software or apps, or on the website of the electrical component supplier, RS.

Using both methods, however, will enable you to verify the accuracy of each of them. So, you should know the relevant formulas for manual calculations regardless.

With a parallel configuration, the individual capacitor values are simply added together to give a total capacitance (Ctotal = C1 + C2 + C3 + …).

But when a series arrangement is used, the total capacitance is always less than the smallest individual capacitor. So, to do this calculation, it will be necessary to sum the reciprocals of the individual capacitances. This means a formula of 1/Ctotal = 1/C1 + 1/C2 + 1/C3 + …

These distinctions mean that if, for example, two 100-microfarad (µF) capacitors were to be connected in parallel, the total capacitance would be 200 µF. However, the total capacitance of two 100 µF capacitors in series, would be merely 50 µF.

Step 4: Check Voltage Ratings

Again, in your circuit design process, the necessary voltage rating check will depend on whether the capacitors are in a series or parallel arrangement.

A parallel circuit entails the voltage staying the same across all components. This means all capacitors must be able to handle the full voltage. If, then, you apply a voltage to such a circuit that exceeds the rating of any single capacitor, the component will be overstressed and fail.

On the other hand, when a series configuration is used, voltage divides, with each capacitor needing to handle its specific share of the voltage. The voltage across each capacitor will be inversely proportional to its capacitance, so small capacitors will experience higher voltage drops.

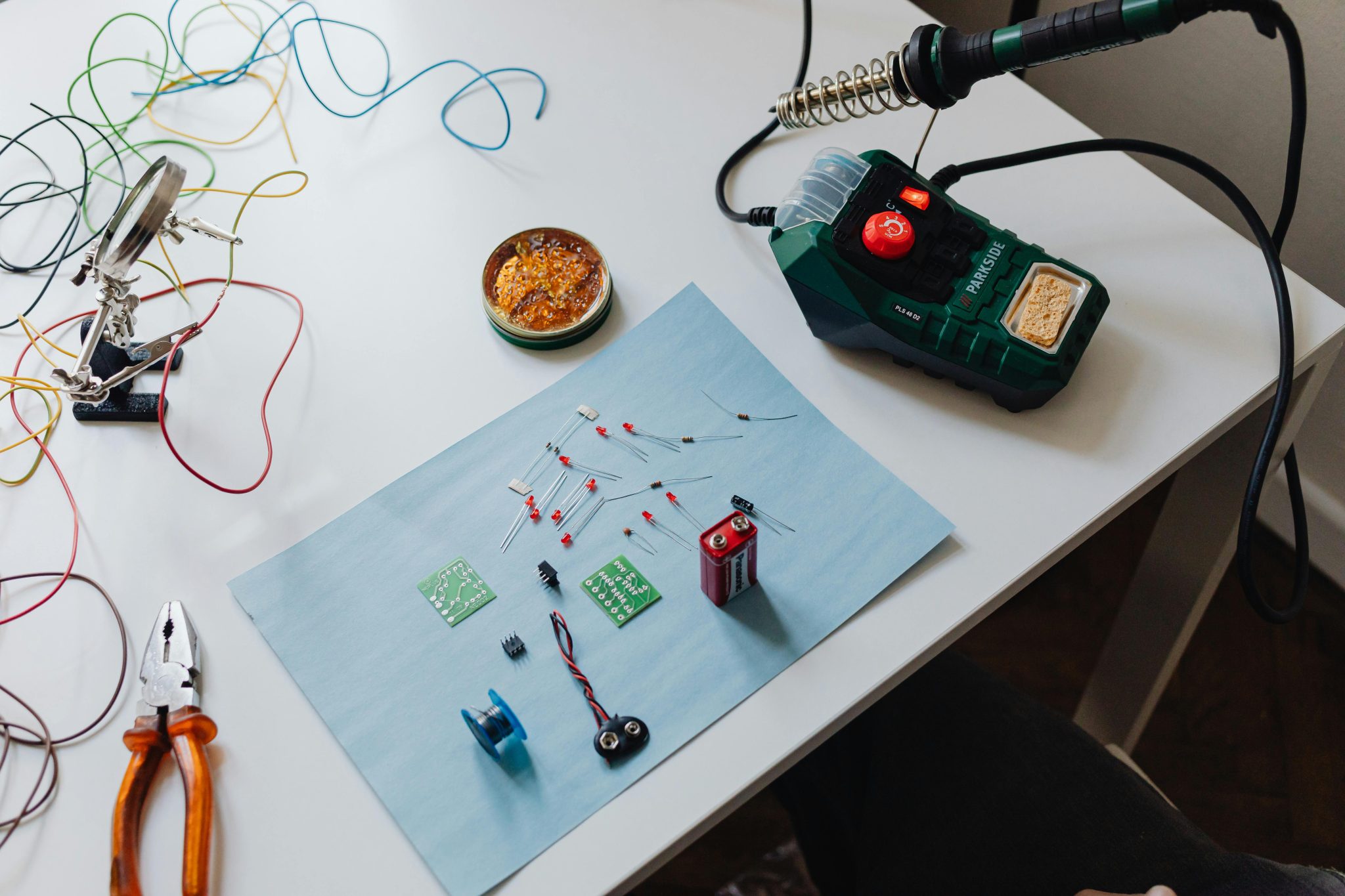

Step 5: Simulate Or Prototype

Before you finalise your printed circuit board (PCB), you can simulate it using software, or prototype it physically on a breadboard. Whichever method you use, it will enable you to verify your calculations and test the circuit’s behaviour.

The use of circuit simulation software is the most effective way to test complex circuits, analyse different behaviours, and pinpoint possible issues, before constructing a physical prototype. SPICE-based tools, such as LTspice and Altium Designer – the letters standing for “Simulation Program with Integrated Circuit Emphasis” – can be invaluable for these purposes.

Alternatively, if you favour a “hands-on” approach or the circuit you’re working with isn’t greatly complex, a solderless breadboard will be accessible and straightforward to use.

Conclusion: Master These Circuit Design Processes to Gain Great Results

We could, of course, go into even further detail on all these “steps”. But as an introductory “takeaway”, this piece will have hopefully got you inspired about how you can begin to confidently design all manner of circuits.

Designing circuits with capacitors in series and parallel configurations is a cornerstone of electronics. Mastering this process, then, can provide a route to a broad variety of innovative and exciting applications and projects.